About Us

Since 1987 (36+ years!), the #1 toner refill kit brand, rated 9.86 out of 10, 166,000+ customers in 157 countries around the world... all started, how?

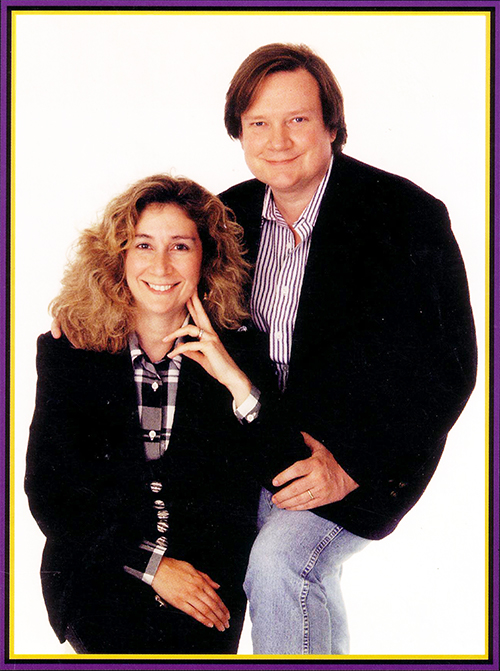

Fate smiled on me when I met my future wife

For reasons still unknown to me, I always wanted to be a stockbroker (or so I thought, kind of like Newman on Seinfeld who always wanted to be a banker... but nowhere near as funny!)

Pursuing that "dream", I joined Merrill Lynch in 1979 in downtown Chicago at the corner of Michigan Avenue and Wacker Drive.

Fate smiled on me when I met my future wife, Annette, there. She had joined Merrill as a broker several months earlier.

(From the start I could tell she was really digging me! (by the way she totally ignored me, refusing to make eye contact with me, feigning zero interest, complaining to HR, the restraining orders... classic signs of playing "hard to get"!))

Neither of us had a clue this was the start of our personal and business life together spanning over 40 years, selling tens of millions of dollars of toner refill kits and toner cartridges, serving 166,000+ customers, keeping millions of pounds of "garbage" out of landfills, keeping millions of quarts of oil from being used to create new cartridges, and 36+ years later still be in a business that has amazing similarities with an industry Carl Icahn is betting billions on (click here for more on Mr. Icahn, the #1 problem most in the toner industry still don't see (though it has been staring them in the face FOREVER!), the worldwide movement that is changing the toner recycling industry (including the folks at Davos endorsing toner refill kits on 1.22.2019!), forever and landmark decision (which we thought we would never see) where the US Supreme Court gave its seal of approval to refilling!)).

She was fantastic in her stockbroker/financial consultant/sales role.

Me? Sitting at some desk in the "bullpen" in a three-piece suit my brain was screaming, "Duane! What the hell were you thinking?"

Fate smiled on me, again, when I "met" my first HP LaserJet Series II printer

By 1987 I escaped from my stockbroker "dream" position and signed on as the head of the "marketing department" for a small software firm.

Fate smiled on me, again, when I "met" my first HP LaserJet Series II printer sitting next to my desk at that company.

Little did I know this "chance" encounter with "cutting edge" laser printer technology would be the start of a 36+ year business with 166,000+ customers in more than 157 countries around the globe.

"Sorry, replace the what?"

The printer was "networked" (using 10baseT coax, also "state of the art") and sat in my "marketing department" area (it turns out, that printer and I were the "marketing department").

One day my boss walked over and said, "You need to replace the toner cartridge in the printer."

Having never seen a laser printer before I said, "Sorry, replace the what?"

He told me to press the button on the top of the printer, open the top, pull out the big black "toner cartridge", throw it away and replace it with a new one (pointing to a blue and white HP box on the floor).

I did what he said and in about a minute the printer was back up and running.

"That thing I just threw away costs $125 bucks?"

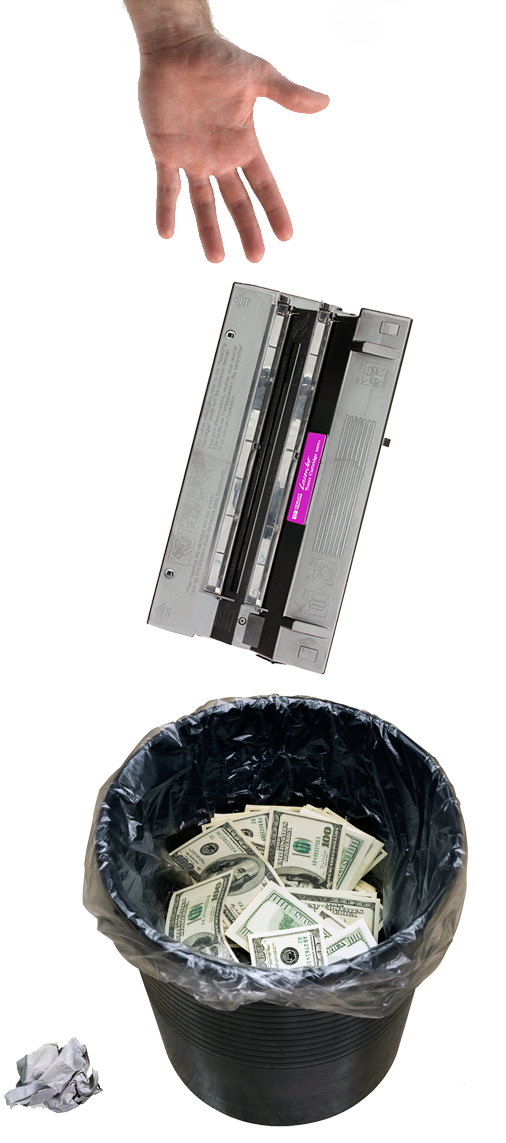

Even though it was the first toner cartridge I had ever seen and replaced, something just didn't seem "right" about throwing it away.

Here's what that act looked like and was happening hundreds of times per day (little did I know, thousands of times per day!)

I asked my boss, "Why throw away the toner cartridge?"

He said, "Because when the display on the front of the machine says, "Toner Low", that's what you do." ("Nice explanation, duh...", I thought to myself.)

I asked, "How much does it cost?"

He said, "$125."

I said, "That thing I just threw away costs $125 bucks?"

He said, "Yes." and started to walk away.

I asked. "How long does it last?"

He said, "About 2,000 pages."

My last question (since he was clearly not interested in chatting about "garbage") was, "If it prints 2,000 pages, how often do you replace it?"

He said, "We go through about two per month."

I loved the thought of helping people be "green" and making some "green" in return

That answer really bothered me.

I couldn't believe the only option was dumping 4 pounds of plastic and metal into the garbage (costing $3000/annually to create that 100+ pounds of "garbage").

There had to be another option.

Maybe refilling it?

In the blink of an eye (literally) my brain saw this!

I wasn't a "tree hugger", but, I loved the thought of helping people be "green" and making some "green" in return.

My brain screamed, "It's empty, not broken!"

In my mind I knew there had to be some sort of compartment inside of the cartridge that formerly had "toner" in it (whatever "toner" was, what did I know?) which was now empty.

All I had to do was figure out how to get inside the cartridge, figure out how to get into that "compartment", figure out where to get some "toner", fill it back up and it would obviously work just fine again.

That's "all" I had to do...

Easy-peasy! Right?

Down to my secret "geek laboratory"

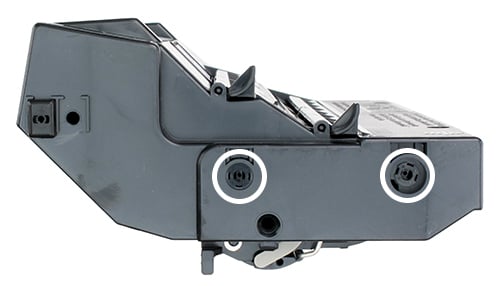

When none of my co-workers were looking, I retrieved that empty cartridge from the garbage so I could take it home with me.

The minute I got home after work I went down to my secret "geek laboratory" (okay, our basement) and pulled out the four pins I had seen earlier.

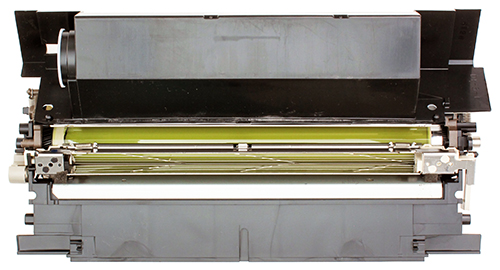

Once I pulled out those pins and removed the cover I saw the four main components of that HP92295A toner cartridge.

(This still puts a huge smile on my face even though it was over 34 years and about a jillion cartridges ago!)

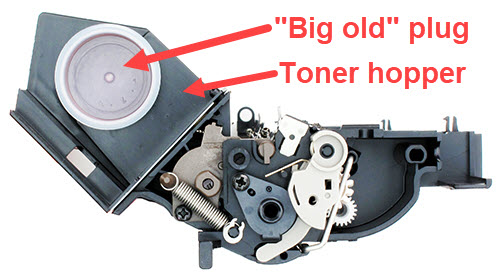

My assumption was correct. There was a plastic "thing" (I soon learned it was the "toner hopper") with a "big old" plug on it.

I pulled the plug and peered inside that hopper with a flashlight.

Though it was almost completely empty, I could see a small amount of black powder ("toner") inside.

Doing more investigation of the cartridge I found another smaller toner hopper that was filled with toner (which I assumed correctly was "waste" toner).

I dumped that waste toner out (Why? It seemed like it was the thing to do...)

Not knowing what I was doing, I carefully cleaned off the green "cylinder" (the "imaging drum") with cotton balls and cleaned the hair-width wire in that silver "cage" (the "corona").

At that point, I was ready...

I knew what I had to do...

I had seen bottles of toner under the Xerox copier at our office, so, I knew what I had to do...

I needed to get my hands on a bottle of toner (since all toner is the same, right? Uh, no. Not even close... More on this in a bit!)

Not wanting to reveal my plans for world laser toner refill domination, I told our office manager my girlfriend's office had the same copier and they were running out of toner and wondered if they could buy a spare since their Xerox rep told them the toner was on backorder.

She said, "Okay." and told me those bottles of toner cost $30 each.

I paid for one bottle and was one step closer to completing my mission.

I knew I was on to something!

When I heard the cost of a bottle of toner was $30 bucks and knowing the HP Series II cartridge sold for $125 I was thrilled.

I figured if I could refill that cartridge for $30 and resell it at a huge 50% discount, I would make $30+ bucks every time I did that.

Now, employing what my friend "Eben Pagan" calls "emotional estimation", I calculated if I just did that a jillion times, I'd make $30 jillion dollars... (and no matter where you come from, that's a lot of money!)

I knew I was on to something!

Girls in the office would swoon at my geek genius

That night I took that bottle of toner home and refilled the cartridge.

I put the "big old" toner hopper cap back into place and then buttoned everything back up.

I couldn't wait to bring it back into the office.

I was positive when I demonstrated my high-tech/money-saving brilliance everyone would praise me and the girls in the office would swoon at my geek genius (Annette's comment, "Oh, honey... good luck with that!")

(Okay, clearly I'm a delusional geek. Many years earlier I thought the girls in 4th grade would really like me after my industrial engineer dad taught me how to use his slide rule... it didn't happen (I still have his slide rule to this day and treasure it beyond words becaues my dad left my life the day before my 21st b-day dying of a heart attack (he was only 49...))

Where is everybody?

I arrived early, as I always did (my dad was responsible for 450+ people at the major company he worked at and raised me to live by his "FILO" (first in, last out) employee philosopy.)

I was waiting for everyone else to arrive so I could start the unannounced show.

Waiting, waiting and waiting, I wondered, "Where is everybody?"

Finally everyone arrived and it was time...

I called all of the other employees (all six of them) and the husband and wife business owners over to the HP Series II and told them they were about to see something amazing.

Explaining what I had done, how I figured it out, how it was going to save the company thousands of dollars per year... no one seemed nearly as excited as I thought they should be.

I knew that would change once they saw it work!

I popped open the "hood", took the newly replaced cartridge out, put my newly refilled cartridge in, closed the hood and asked "Angela" (the wife of the husband/wife business owner team who sold me the bottle of toner) to print out our 12-page company literature.

She queued it up and after what seemed like forever the printer started printing.

"Maybe you should have tested this, first, "genius"..."

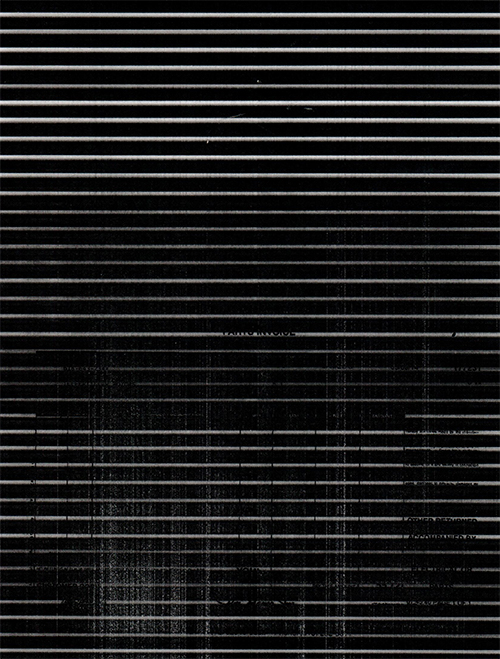

The first page started to come out, face down on the top of the printer.

I proudly lifted it up only to see (at the same time everyone else did) the entire page was a dark grayish/black and the text was white on that terrible-looking background.

(Remember when I said, "All toner is the same, right?" I and all of my co-workers just learned, it's not! Not even remotely close.)

Though this isn't exactly what it looked like, it's darn close...

It wasn't bad enough that the first page was like that.

No one stopped the print job...

They were too busy laughing and saying something complimentary like, "Maybe you should have tested it, first, genius..."

I am embarrassed to admit that though I arrived 30 minutes before everyone else, in my excitement it never occurred to me to run even a single test print before showing anyone else.

That's a perfect example of what Zig Ziglar calls "the confidence that goes with ingnorance".

Live and learn... (every single cartridge we ultimately went on to remanufacture was tested for print quality)

"If that had worked, Duane, it would have saved us a lot of money."

When everyone but "Frank" (the other half of the husband/wife owner couple) left, he said, "So, the first try failed. If that had worked, Duane, it would have saved us a lot of money."

His comment had two effects. One minor, one MAJOR.

The minor effect, it made me feel somewhat better.

The major effect, it convinced me...

This was a REAL business opportunity!

I was on a MISSION!!!

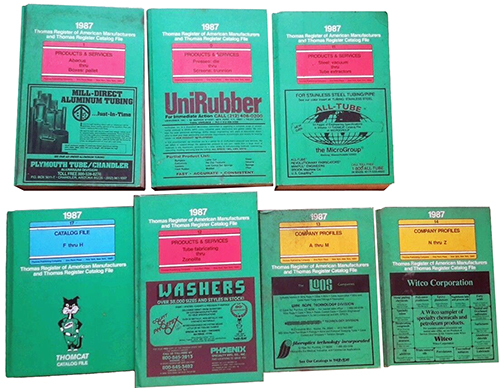

Since this was before the internet was "invented" I had to do homework on this whole toner cartridge refilling thing the old fashioned way.

I had to leave my couch (the horror!) and physically go to the library (remember doing that?).

Thanks, again, to my dad who was in manufacturing, I knew of the giant green set of "Thomas' Manufacturers Directory" books.

I didn't know what I was looking to do was "officially" called so I didn't even know what categories to look under.

But, I had access to those books, had the time to do the homework and...

I was on a MISSION!!!

From digging through page-after-page-after-page of listings, I found what I felt were good possibilities and subsequently made tons of phone calls and got leads on suppliers, manufacturers and other insight.

"It's called 'toner cartridge remanufacturing'."

Finally, on one of the calls a grizzly sounding "old" guy (Burt Jacknow at "Carbotek") told me, "Yeah, we have what you are looking for. We make toner for Canon printers. And, the process you are talking about is called toner cartridge remanufacturing."

I told him. "I'm not interested in Canon printers (duh! Alright, I left out the "Duh!"), but Hewlett Packard printers."

He went on to tell me HP laser printers weren't (and still aren't) made by HP, they are all made by Canon.

Becoming a little less grumpy he explained that the printer industry was just like the automobile industry.

There are primary (OEM - original equipment manufacturers) manufacturers of the printers that produce their machines under the "badges" or brands of other companies built to their specifications (the way the printer looks, how the interface works, does it offer postscript, etc.) to make it "their's" and they pay the underlying manufacturer to make it for them.

At the end of the call he provided the names of a few companies in the business of "training" toner cartridge remanufacturers as a business opportunity.

The thought then occurred to me to go to a local "newsstand" (remember those, too?) to search for more companies that offered training.

I spent hours there. I bought a bunch of business opportunity magazines to look for ads from companies offering toner cartridge remanufacturing training.

I found about half a dozen companies offering that training.

I called them and requested their literature (again, pre-internet... no instant gratification).

During those calls I learned the least expensive training I found was $5,000 and the prices went dramatically higher from there.

Yikes!

"Jay knows a guy who trains people to remanufacture toner cartridges!"

At lunch with her stockbroker pals/partners, Annette mentioned my days-old business plans to remanufacture toner cartridges.

In an amazing coincidence one of her partners also had toner cartridge remanufacturing appear on his radar when he was looking for business opportunities for his recently retired father.

She called me immediately and said, "Jay knows a guy who trains people to remanufacture toner cartridges!"

Supposedly Jay's friend "Gordon" was already in the toner cartridge remanufacturing business, part-time, and a full-time high school guidance counselor.

He was willing to share his "secrets" in a one-day training session in the basement of his home in a suburb of Minneapolis.

As if I wasn't unimpressed enough already, the HUGE mistake she made was adding, "And, he only charges $500 dollars for his training so we don't have to spend $5000!"

I told her, "Yeah, great... We'll talk about this tonight when you get home."

"If he doesn't know what he's doing, don't pay him. If he's bigger than you are, pay him and stop payment on the check."

When Annette got home that night she asked, "Why aren't you excited about Jay's "guy"? He sounds perfect."

I said, "Honey, you know the training firms I found charge, at a minimum, $5000 dollars and some as much as $50,000 bucks. Do you honestly believe for $500 bucks some guy in his basement is going to teach me everything the training firms are going to teach?"

I added, "And, if he is so good at what he does, how come he still works as a high-school guidance counselor?"

Once again, Annette nailed it with her response.

She said, "You're smart. If you go to get trained by him and feel he doesn't know what he is doing, don't pay him. If he's bigger than you are, pay him and stop payment on the check. But, if he does know what he is doing, we just saved almost $5000!"

I couldn't argue with that (plus, I knew I wasn't going to win that argument even if I tried.)

I fully expected to take Gordon's training, find out it wasn't worth it, come home and still go for the "real" at one of the "real" training firms.

That night I called Gordon and made the plans to go get trained.

Excellent toner cartridge remanufacturing "training", saving $4500 bucks and Tater-Tot casserole! #WINNING!

A few weeks later, on a Friday in November in a super-cold, super-snowy midwestern winter I drove from our Chicagoland area home to Minneapolis.

Bright and early the next morning I was in "Gordon's" basement.

I got my questions out of the way, early (the primary one being, "Hey, if you are making so much money doing this, what's up with that high-school guidance counselor job?" (it turned out he was a few years away from retirement and would forego his pension if he quit... Okay, made sense).

I also told him of my failed experiment and he said, "All toner is not the same." (Duh, figured that out on my own, Gordo!)

And, the problem was laser printers require positively charged toner. Copiers use negatively charged toner.

If you put negatively charged copier toner into a laser printer cartridge (or vice versa) exactly what I had happen, will happen.

He seemed like a really knowledgeable and honest guy so I was feeling better (but still not completely convinced I was going to learn "everything").

But, within an hour of standing at his side I had remanufactured my first Canon EP-S/SX (aka, HP 92295A/HP Series II cartridge) and it worked, perfectly.

Standing at his side for the entire day, he showed me everything he knew about the fledgling toner cartridge remanufacturing industry.

There were only four printer "engines" (the guts of the machines), all made by Canon at the time (today there are hundreds of "engines" that have come and gone.)

He taught me to remanufacture the Canon "CX", "SX" (two laser printer "engines") and the Canon "PC-Large" and "A15/30" (two desktop copier engines).

It turned there were about the same number of suppliers of toner at that time and the quality of that "aftermarket" toner ranged from "not so bad" to "bad" to "worse" to "God awful"!

The best part?

Not only did Gordon truly know how to remanufacture cartridges as well as the firms that wanted $5 grand and up (so we saved $4500 bucks), his wife made "Tater-Tot" casserole for lunch that day.

Now that's what I call winning!

"Wait, how much are you making?"

Over lunch I asked Gordon if he would share with me how much money he was making and he did.

When he told me those numbers I was shocked and said, "Wait, how much are you making?"

He was selling cartridges for 50% of the OEM cartridge price.

His profit margin at that price was nearly 75% (about $40 - $50 for 30 minutes worth of work!)

Working part time at this, he was remanufacturing 80 - 120 cartridges per month.

$3,000 - $6,000 per month, part-time, working out of his basement...

That'll buy a TON of Tater-Tots!

How to market this...

On the drive home all I could think of was how was I going to market this?

Given my cold-calling background from Merrill Lynch (250 dials each day before you go home!) that seemed like the best (and cheapest) way to start.

I started prospecting for my business during my lunch hour.

My goal was to get at least 40 - 50 cartridges/month under my belt and then quit my job.

Though there are some people who truly enjoy cold-calling, I wasn't one of them.

But, I figured calling to find people who used laser printers and then offering savings of 50% or more on something they were already buying would be way easier than calling people out of the phone book in "ritzy" suburbs trying to get them to invest money in some stock I was recommending.

I was right!

If you don't have a garage, get one!

When I worked at E. F. Hutton, Hugh Bowles (you can probably figure out what his nickname was...) introduced me to Zig Ziglar.

I have been a huge fan of people of Zig's ilk ever since then.

I remember the first time I saw Zig in person. From the stage he said, "When you are brand-new at something, act like you know what you are doing, act like you are farther along than you are... Fake it 'til you make it."

So, even though we were just starting "The Laser Group" out of our townhome, I wanted to "fake it 'til I made it".

I didn't want to come across as some wannabe businessman operating out of my basement, I wanted to project an image of an established business my prospects could trust.

BTW, in no way am I looking down my nose at people starting businesses in their homes.

David Packard and Bill Hewlett started HP in the one-car garage in back of Dave Packard's house.

Apple was started in a garage.

Google was started in a garage.

My absolute best business advice to anyone looking to start their own business?

If you don't have a garage, get one!

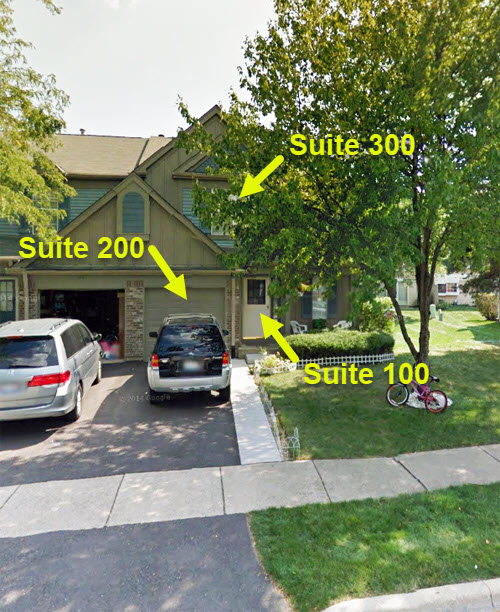

Suite 100, Suite 200 and Suite 300

With the idea of trying to present that, "Yeah, we're a real business!" appearance, you'll see in the PC Magazine ad coming up later that I added "Suite 100" to our street address to make it sound like a business address.

And, I would tell our suppliers that "shipping and receiving" was Suite 200 (which was our one-car garage (see? You need a one-car garage!) that very rapidly was completely taken over by incoming cartridges and supplies.)

R&D was Suite 300 (a spare bedroom office which was were Annette ultimately worked).

And, though we didn't add a "Suite 400", "production" was our basement where "Winky" (our Sheltie) and I would work all day and well into the night.

"The quality is good, not perfect. But, think of all of the money you will save!"

At that early stage in the toner cartridge remanufacturing industry, toner was the only supply available (no new drums, developer rollers, wiper blades, etc.)

Plus, even the "best" toner at the time wasn't the equal of the original (not as dark, distinct, didn't have the same "yield" (number of pages), etc.)

Rather than hiding it, I made it my selling point.

I told prospective customers right up front, "The quality is good, not perfect. But, think of all of the money you will save!"

Some were real sticklers for the ultimate in quality.

But, more than enough prospects were intrigued by my suggestion, "Use our remanufactured toner cartridges for all of your daily, in-house printing and when you really have to produce the best quality take out our remanufactured toner cartridge and put in the much more expensive brand-name cartridge."

It wasn't ideal, but for a lot of people it worked.

It saved them a lot of money, it made "The Laser Group" good money.

A "Win-Win".

Plus, I knew the quality would definitely improve as time went on so I just had to manage their expectations and do the best I could in the meantime.

Nordstrom would be taking customer service lessons from us!

From the very start I knew that if/when my remanufactured toner cartridges and those of my competitors worked as well as the name-brand OEM originals the only differentiation I would have between our company and the other guys was our price.

Though I am not a genius, I was smart enought to know I didn't want to start a business with a "race to the bottom".

That concern made me decide the way we to set ourselves apart from everyone else was offer the best customer service and support we possibly could.

I set out to do that so well that the company recognized for legendary customer service (Nordstrom) would be taking customer service lessons from us and have to step up their game to be as good as we were in that regard.

"No time limit - No fine print" guarantee

That's how I came up with our "No time limit - no fine print" guarantee.

It meant exactly what it said (and still does to this day), if for any reason, at any time (even years later) you are disappointed in our products, service, even the color of the box(!), you are entitled to a refund or replacement (and, the choice of which is up to the customer).

It scared the bejeepers out of us to offer that sort of over-the-top guarantee, but to this day we can count on one hand (okay, maybe two hands) the number of times we have been taken advantage of.

It has served us extraordinarily well (and, we are still the only company in our industry that offers it!)

YIPPEE!!! I was able to quit my job!

By solely cold-calling local businesses in our Chicagoland area I was able to quit my job.

That was over 34 years ago.

But, my "brilliant" business plan still had me picking up and delivering cartridges and that took a lot of time.

Fate smiled on me for a third time

One day, sitting in my car in the town of Schaumburg (about two hours round-trip from where we were based in Westmont, IL) I was stuck behind a UPS truck that was making a delivery at a business.

When the driver opened the rear door, I saw three HP LaserJet Series II cartridges (they were (and still are) easy to identify boxes and they were now my life.)

Fate smiled on my for a third time when I saw that. "Duh, let UPS do the pickup and delivery!"

Though being able to ship remanufactured cartridges was problematic at the time (the "seals" at the time were wishful thinking and could leak toner (especially when shipped long distances)... oops!).

Getting set up to be a UPS shipper (from the "shipping dock" (our garage at our townhome)) was the key to explosive growth.

No longer wasting time acting like a delivery driver, I could ship cartridge to our customers.

And, that meant...

National advertising in "PC Magazine"?

I realized if I could ship a cartridge across northern Illinois and the Chicagoland area (where we started our business) the entire United States was now my oyster!

That thought lead to the massive increases in our business when I conviced my wife (who was still working in the brokerage industry) we needed to run an ad in a national magazine.

PC Magazine was my choice but it was hugely expensive.

A one column inch ad in the "Marketplace" ("low-rent" classified ad section in the back of that magazine) was $1500 bucks (every two weeks).

But, it was 1990, laser printers were still brand-new, it was PC Magazine and it was really popular.

So, we went for it. We still have the same phone number to this day!

(I found this on Google in their magazine "archives". That brought back a flood of memories!)

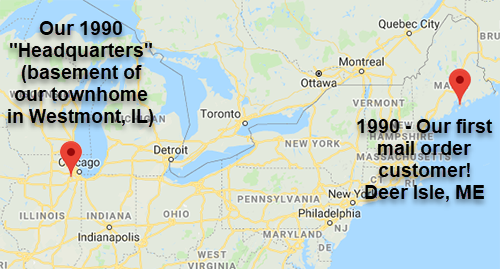

"Where is Deer Isle, Maine?"

I can remember it as if it was yesterday.

From that really cheesy looking ad (I was so proud of it at the time!) the first phone call we received was from a guy in Deer Island, Maine.

He agreed to pack up and ship three toner cartridges to us (at his expense), we would remanufacture them and then send them back to him (again, at his expense).

He was our very first mail-order customer!

I had to check an atlas (look that up, kiddies, it was pre-internet, no Google Maps) to find out where Deer Isle, Maine was located.

In the blink of an eye, we just went nationwide.

With all of the bluster of a basement-based business owner with dreams of world domination (who works with his dog all day long), I said, "Sure! If we continue to advertise nationally we will probably be remanufacturing 200 cartridges per month by the end of the year. So, if we continue to grow, someday that will happen!"

"You did what?"

Though it wasn't the next day, it wasn't long thereafter when Annette came home and while we were waiting for our pizza and Italian beef meal at "Papa Passero's" (our favorite pizza place up the road from us in Westmont, Illinois) she casually said, "I did it."

I said, "You did what?"

She said, "I quit. I am no longer a stockbroker!"

I said, "Yeah, that's funny. What did you really do?"

She said, "I am not kidding, I quit."

Panick-stricken, I said, "You've got to be kidding! You quit? Effective WHEN???"

She said, "Today! Today was my last day at work. Tomorrow is my first day working full-time with you."

I took it quite well (if I overlook my sheer terror, panic, sweating, loss of appetite, fear, spinning head, nausea...)

That's when "stuff" got real (in a really, REALLY good way!)

I am not joking when I say I was terrified (we just lost our main source of income).

Though I knew The Laser Group was growing, that's when "stuff" got real (in a really, REALLY good way!)

Annette having the guts to take that giant leap was the best thing that ever happened to The Laser Group.

In her first full year onboard we did 6X the business we did in our first year.

The next year we did 2.5X the prior year.

We kept hammering on national ads and continued to cold-call and our business exploded from 100 cartridges per month to 5000+ cartridges per month.

We kept growing and growing and growing and out-grew our townhouse (we actually out-grew it way before I finally decided we had to get real commercial space).

We moved into commercial space in... DeKalb, IL?

Rent in the western suburbs of Chicago was too high so we moved into commercial space (the basement of an old bank building with 30" thick stone walls) in DeKalb, IL, where I "grew up" (that's in quotes because Annette still contends I have not grown up...)

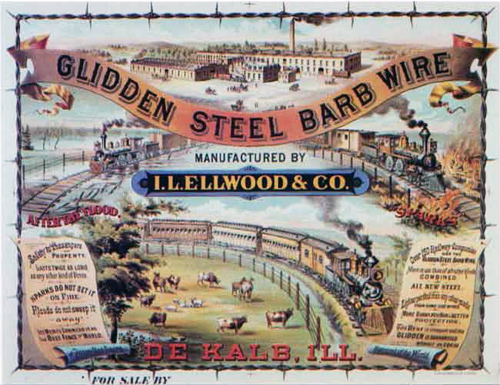

Alright, if you are one of the few people on the planet who isn't familiar with DeKalb, IL, DeKalb is the home of hybrid seed corn.

DeKalb is also the home of barbed wire (and our DeKalb High School sport teams were, the "Barbs", of course!)

DeKalb is the birthplace of Barbara Hale, aka "Della Street" from the old "Perry Mason" show (which if you aren't "older than dirt", as am I, probably means nothing to you and you also probably wonder, why are they in black and white?)

Okay, and one last notable DeKalb bit of trivia, Cindy Crawford also hails from there (went to the same high school, went to the same local watering holes... Just like Annette she feigned zero interest in me, as well!)

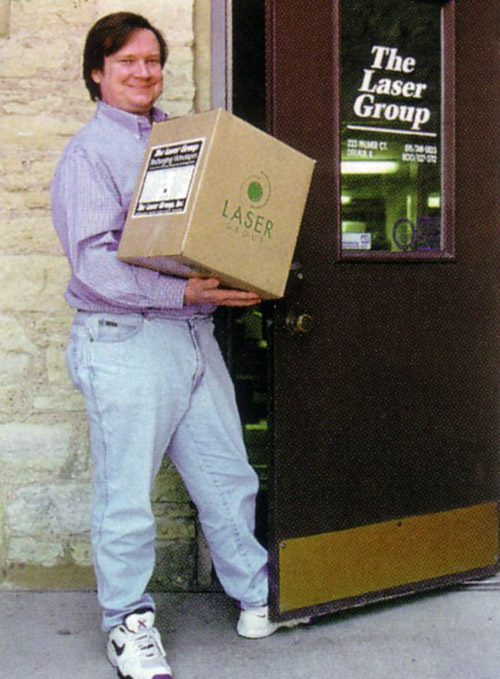

Oh, and how could I forget, DeKalb is also what is considered the home of "The Laser Group", of course (go ahead, make fun of me... I was a tad "chunky" back then!)

Beyond that brown door...

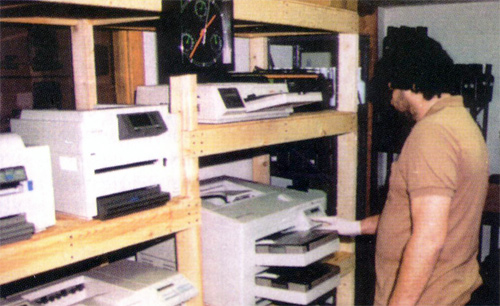

That door was the primary entrance to our first commercial space.

Through that door through 5,000+ cartridges arrived every month (250 per day!) and all of the supplies to remanufacture those cartridges and the people responsible for remanufacturing those cartridges.

Each cartridge had to be checked in, unboxed, pre-tested, completely disassembled, remanufactured, refilled, re-assembled, post-tested, packed-up and shipped back to the customer.

So, 5,000+ cartridges departed through that door every month, as well.

Though it was a lot of work, we loved what we were doing, we loved working with our customers (because, as cliche as it might sound, we knew from day one that without them we wouldn't have a business).

We also knew that to keep growing we needed more and more "people", our employees.

For 34+ years we have been really lucky and have had great people working with us.

(Okay, we have had a few "ringers" along the way. What business owner hasn't had that occasional employee that makes them say to their spouse, "What were we thinking???")

Just like customers, we knew without great employees we would go out of business.)

When that picture was taken "The Laser Group" and our toner cartridge remanufacturing business was in a good place.

Or, so we thought...

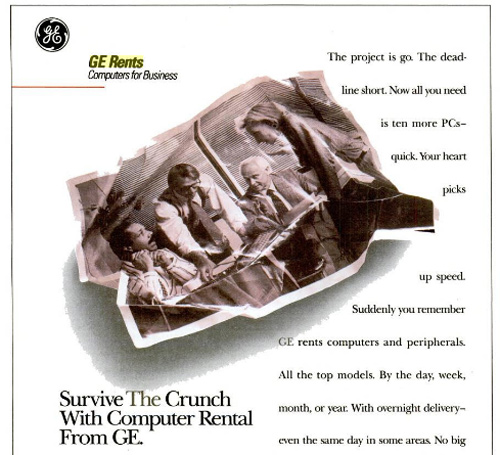

Our biggest customer of all time was "GE Rents"

Our biggest customer of all time was "GE Rents".

I don't know if they still do what they did back then (I just searched Google, it appears they don't...), but, they would rent technology equipment to companies displaying at trade shows (and anywhere else it was needed).

They were capitalizing on the fact it was next to impossible for people to bring/ship PCs, monitors, keyboards, printers (yeah, laser printers!) to trade shows across the country and there was a huge opportunity to rent them that equipment.

They were our DREAM customer.

They rented laser printers.

They rented TONS of laser printers.

They rented TONS and TONS of laser printer cartridges.

They basically rented only one type of laser printer (the HP Laserjet Series II/EP-S/SX cartrdge).

Their rented/returned cartridges were almost always lightly used, maybe produced a few hundred pages and were PERFECT for remanufacturing.

Their business, alone, had grown to become more than half of our business (uh-oh, are you hearing "eggs and basket" somewhere in your head?)

Every Monday morning their truck showed up packed front-to-back, left-to-right, top-to-bottom and the "troops" would rush out to unload them.

Though we were selling them cartridges at a HUGE discount, we pushed all of our full-retail, "onesy-twosy" LOYAL customers' (who had brought us to the point where we were able to advertise nationally) cartridges to the side every week until we had GE's cartridges done and then we would get their cartridges done.

We hadn't pursued GE Rents, we hadn't cold-called them, we didn't go "elephant-hunting" and find them, our ads in PC Magazine did that job.

GE Rents found us.

"What the national advertising "Gods" give you really fast, they can take take away even faster..."

I am a firm believer that no matter what someone tries to teach you, the best lessons are the ones you learn the hard way.

You don't often hear people say, "Things were going perfectly and that was when we learned the most important things about (whatever)..."

Almost always you hear, "This really bad (whatever) happened to us, but, because that happened, here is what we learned and it was HUGE!"

So, we were about to learn the hard way that...

What the national advertising "Gods" give you really fast, they can (and will) take it away even faster....

"Hey, boss, the GE truck don't show up."

Another "I can remember it like it was yesterday..." (though it was 25+ years ago) moment in our business life.

It was just like any other Monday morning (at least up until this moment) and Francisco came up to me and said, "Hey, boss, the GE truck don't show up."

I looked up at the clock (I stopped wearing a watch the day I stopped working for anyone else... little did I know it wasn't because of the "freedom" of working for myself, it was because I didn't need to wear a watch because I was always working!) and thought, "Huh, it is 10am. They should have been here two hours ago."

I told Francisco, "Don't worry about it. Until they get here we can hammer on all of the other cartridges and actually catch up a little."

Being the take-charge boss that I an, I then did what any "I'll fix this!" boss would do, I went to look at the parking lot for myself... (What was I thinking, maybe they somehow overlooked a giant truck?)

Little did I know, GE Rents' truck was never, NEVER going to show up again.

We were actually sort of relieved their truck hadn't shown up...

That first week we didn't call GE to find out what, if anything, "happened".

In fact, we were actually sort of relieved that their truck hadn't shown up.

We were able to take a breath, catch up on so much of the backlog of the "onesy-twosy" customers. (Thank you, God, again, for blessing us with 266,000+ "onesy-twosy" customers over all of these decades!)

"We switched to another vendor."

The next week I just happened to be up in the front of our space, sort of pacing by the front door watching and waiting for the GE truck.

I knew it would come.

Okay, I am lying, I was hoping and praying it would come.

But, my brain was telling me, "Duane, the truck isn't going to come today, either!"

My brain was right (damn you brain!!!), their truck didn't show up.

Without even making the call, I knew why...

But, I did call our contact and they gave me the news.

"We switched to another vendor."

The reason? $.53 cents.

53 CENTS!!!

They found a competitor who was charging $.53 cents per cartridge less per cartridge.

And, they didn't even let us know they were leaving!

"53 $*%^& CENTS!!!"

Was that "fair"? Absolutely.

They were free to do what they want.

My "They let us for 53 $*%^& cents!" rant (to myself and Annette) missed the point.

That 53 cents was saving them $2,000+ per month, $25 grand per year.

And, they told me our job should have been to proactively lower our price over time to retain their business.

Had we done that, they wouldn't have left.

And, I thank God they did (not at that moment, of course) but it lead to so many other great things.

Funny how that works, isn't it?

"How in the world are we going to find another GE Rents?"

I got off of that call and told Annette the news. We just looked at each other.

"Stunned" doesn't even begin to sum up our feelings.

More than half of our employees were dedicated to that single customer.

Without saying it we both knew exactly what the other was thinking.

If we don't replace that business, we are going to have to fire 60+% of our employees.

Annette said, "How in the world are we going to find another GE Rents or another 3,000 cartridges a month?"

I said, "I have no idea." and walked out of her office.

"OMG, is it really that easy?"

I am a habitual early riser and always have been.

When Annette got into the office that morning I practically ran into her office and said, "I've got it. I know what we need to do!"

She looked at me skeptically and said, "What...?"

I said, "We don't have to replace 3,000+ cartridges per month. We don't have to find another GE Rents.

Annette said, "How can that be? What's your plan?"

I said, "It's not about replace the number of cartridges, it's not even about replacing the lost revenue."

She said, "Okay, I give up, then what's it about?"

I said, "We only have to replace the lost profit!"

I have done the math and figured we only needed to find 217 one-cartridge per month retail customers or 109 two-cartridges per month customers to replace the profit we were making off of GE."

That's how steep we discounted our cartridges to secure GE's business when they approached us.

We made 15X more profit on a single retail cartridge (and our retail price was still among the lowest in the remanufacturing industry) than we made on each GE cartridge.

Annette's response was, "OMG, is it really that easy?"

I said, "It really is that easy!"

We knew with 100% certainty how to find "onesy-twosy" customers.

We had no doubt we could find another 100 - 200 of them without a problem.

And that's exactly what we did over the next few months.

That "disaster" lead to my "The pyramids of Egypt" philosophy

Thinking about that over the years, that "disaster" lead to my "The pyramids of Egypt" philosophy.

Looking back I realized the reason our business blew up was our very existence depended on one giant customer.

Up until GE Rents found us, we intentionally avoided "elephant hunting" (sales parlance for seeking out customers who use dozens, hundreds or thousands of cartridges per month).

On the other hand, the thousands of onesy-twosy customers we had built our business on up until then created a tremendously strong foundation.

Though all of our onesy-twosy customers were important to us, not a single one of them, not a few dozen, not even a few hundred of them disappearing could destroy our business.

And, we could find more and more and more of them.

It was the exactly like the Pyramids of Egypt.

The pyramids hadn't lasted thousands of years because they were carved out of one giant stone, they lasted that long because thousands and thousands and thousands of "little" "bricks" were piled on top of each other to make a massive structure that to this day can be seen from space.

From that day forward, we aggressively followed our "Pyramids of Egypt" strategy.

It's a "WIN - WIN" if their savings means as much to them as the profit means to us

That "Pyramids of Egypt" philosophy made us develop another core business philosophy...

It's a "WIN - WIN" if their savings means as much to them as the profit means to us.

That idea has been with us since that day.

"People REALLY want us to teach them how to remanufacture toner cartridges!"

The minute we started advertising in PC Magazine ads we started receiving inquiries from people who wanted to start their own toner cartridge remanufacturing business.

I was totally opposed to it (I wanted to keep the opportunity all to ourselves!).

Fortunately, Annette (who always is the voice of reason and has a keen eye for profit opportunities), disagreed.

She brought it up, again (I think we were at Papa Passero's, again) and said, "Honey, people really want us to teach them how to remanufacture toner cartridges!"

She added, "I think we should do it."

Of course, I said, "No."

Never one to give up on something she believes in she asked these four key questions:

- "How many cartridges are being sold annually in the United States?"

(Even back then it was nearly 60+ million cartridges!) - "What percentage of those are we remanufacturing?"

(At 5,000/month, 60,000 per year, we were remanufacturing 1/10th of 1% of all the cartridges that could be remanufactured.) - "How many can we possibly remanufacture?"

(I told her even with our 1/10th of 1%, I couldn't fathom the space, the equipment, and the employees(!) needed to even double or triple our production, let alone aim for 1% of the market.) - "How much do you think people would be willing to pay for training?"

(She already knew the answer as I had previously tried to convince her I absolutely "needed" the $12,000 training offered by one of training firms in the fancy magazines!)

The answers to her questions lead to our "training division"

We discussed it further...

Toner cartridge unit sales were rapidly heading toward 100+ million per year.

There was no way we would ever come close to remanufacturing even 1% of them.

While scalable, toner cartridge remanufacturing was labor and space intensive.

The thought of creating a series of training videotapes, manuals and a starter "Business In A Box" with supplies was quite appealing.

Once again, not knowing anything about how to produce videos, I hunted down the answers.

What is "linear editing"?

This was so long ago (yes, we have been in the toner business for a long, long, long time!) about the only way to make videos (that we could afford at least) was to record your source material on S-VHS tapes.

Then, in order to produce an actual well thought out edited final product, you did via something called "linear editing".

What is linear editing you ask (as did I at the time)?

Linear editing meant you used video "tape" decks with real, physical tape (look that up, kids!)

You recorded the source materials on tape and then to create the edited master the source tape would be wound back and forth (linearly) to find the spot on the tape where the material was you want to copy to the record deck.

Within roughly three 3 months I had created the best toner cartridge remanufacturing videotape training, manuals and marketing materials available anywhere (even the super expensive training wasn't as good as ours!)

In the first year we sold nearly 500 sets of video tape training and our "Business in a Box" toner cartridge remanucturing tools and supplies.

As the number of printers, faxes and copiers our training covered increased, we needed to speed up video production.

We moved to "non linear" editing (no more tape, computer hard drive based, which is what everyone uses today) starting with the Amiga "Video Toaster".

And then moved on to an IBM PC-based "Fast Video Machine" from "Fast Video" out of Germany.

We ran ads print ads for our training in Entrepreneur Magazine, Inc., Income Opportunities, New Business Opportunities and a number of others.

Ultimately we trained over 3,500 people around the world how to participate in the booming toner cartridge remanufacturing industry.

(We sold our training and our "Business in a Box" starter supplies for far less than anyone else in the industry (a total of $1500). Unlike any of our competitors in the training space we didn't require our trainees to buy their supplies from us. Our training included our completely vetted suppliers list in our materials (the same suppliers we were using every day to pump our cartridges out the door). Looking back it caused us to miss out on a huge source of on-going revenue, but, knowing we provided so many people the best materials to start their own toner cartridge remanufacturing business who couldn't have afforded any of the other training out there is still a source great pride.)

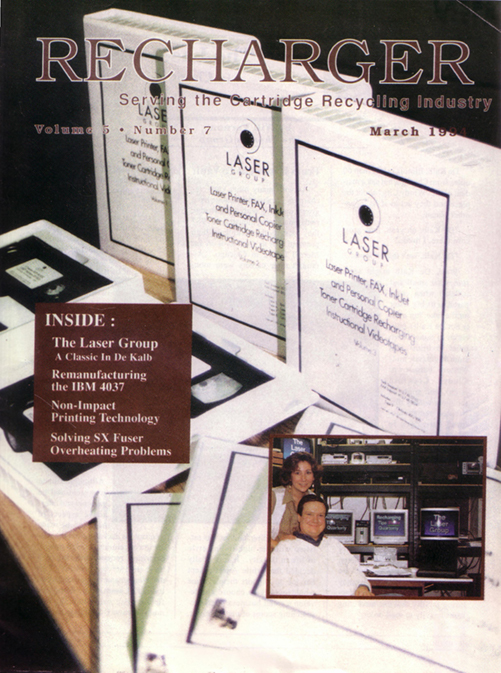

The toner cartridge industry takes notice

Not only had Annette and I grown a remanufacturing operation in a short period of time to the top 5% in the industry in terms of monthly cartridge volume, we had also become the largest trainer of others in the industry in an equally short period of time.

Without any self-promotion (this was well before the internet, Facebook, Google, selfies...), what was interesting was people in the industry were hearing about us.

The toner cartridge industry took notice and both of the main industry publications came to Illinois to do cover stories on our company.

"Recharger Magazine" - the first industry publication

The first article about our company (still called "The Laser Group" at that time) focused on our toner cartridge remanufacturing training. In addition, it included an in-depth look at our toner cartridge remanufacturing operation.

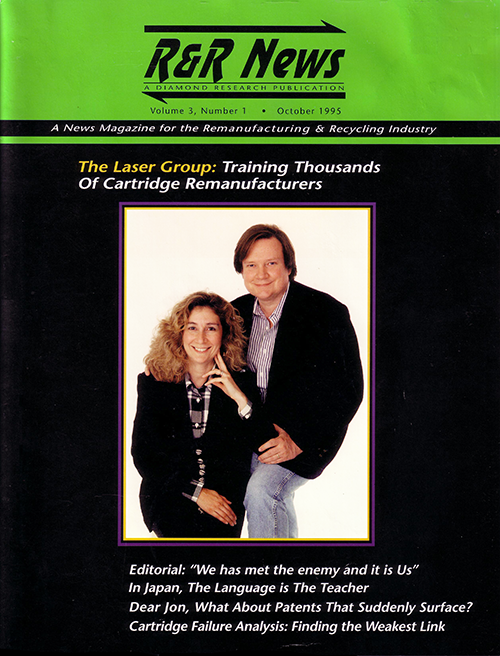

"R&R Magazine" - the up-and-comer

Roughly half a year later, Art Diamond, the "godfather" of the toner industry (founder of Diamond Research Group, the publishers of R&R Magazine) personally came out to interiew Annette and me after hearing so much about our growth in both the remanufacturing industry and the training industry. (It was the beginning of a 20+ year friendship. Unfortunately Art passed away in 2016.)

Fate smiled on us in the biggest fashion, EVER!

In late 1998, I happened to be looking through a "Tiger Direct" "magalog" (combination magazine/catalog) and saw a "story" (ad) about a "toner refill kit" from some small company I had never heard of prior to that time (and basically never heard of them thereafter.)

Their toner refill kit was a bottle of toner (from a supplier we immediately recognized as one we use because of the distinctive shape of their bottle), a soldering iron with a piece of 1" piece of copper pipe stuck on the end heating element using the set screw that should have held the soldering tip in place and half of page of instructions that didn't address any of the components inside the cartridge, nothing about emptying the waste hopper, it was solely poke a hole, pour in some toner, you are "done".

The most amazing part? They were selling that "kit" for $25 (and if you ordered another kit, it, too, came with another soldering iron).

"Hello, TigerDirect?"

I immediately called TigerDirect and talked with the person responsible for that ad.

I told them we were in the toner cartridge remanufacturing business and the toner cartridge remanufacturing training business and based on our massive experience in hands-on remanufacturing and teaching people how to remanufacture cartridges using our exact same process, I could create a much better kit showing people how to remanufacture cartridges "the right way".

When I was met with silence, I reiterated, "We can create a DIY toner refill kit that will be far better, far more complete and for the same price or less.

His completely underwhelmed, uninterested response? "Call me when you do that."

"What do you mean we already do that?"

That response made me mad.

So, once again I set out on a mission to create the best toner refill kit in the world.

I showed our remanufacturing operations manager, "Francisco" the picture of the cheesy toner refill kit I found in the magalog and said, "Look at this, with our training, our tools, our techniques, we can make a kit so much better!"

(Here's Francisco testing an HP 92291A cartridge in HP's then latest printer, the HP IIISi)

He looked at the picture and said, "We already do that."

I said, "What do you mean we already to that?"

(From day one my edict was when we remanufacture our customer cartridges would would do the absolute best job we possibly could to make certain they worked as close to the OEM as possible. That meant we take them apart completely, totally clean them out, replace all critical image production components, replace the toner, seal the hopper, we do it the absolute best way possible.)

Before he could answer I continued. "We don't do some "cheesy" toner-only, so what are you talking about?"

Francisco went on to inform me that for as long as he had worked for us, for all of the cartridges we used in house (not customer cartridges, "our" cartridges) when they ran out of toner, he would pop the cover, empty out the waste toner, add new toner, put it back together in about 1/5th the time and for about 1/5th the expense.

That seemed like nonsense to me. I said, "There's no way that will work."

He said, "It does work, it works 2 - 4 times before critical components finally wear out and need to be replaced."

I was speechless... (a rarity, for me, just ask Annette or anyone on our team.)

So, he said, "Boss, if you don't believe me next time I do it I will show you."

I still didn't believe what he was telling me

Despite the fact that just a few years earlier when I received my "training" there were no replacement components available and the entire "remanufacturing" process was just open up the cartridge, clean it out, add toner, put it back together (a "cheesy refill" but my standards just a few short years later), somehow I still didn't believe what he was telling me.

Rather than wait for us to need a cartridge to be refilled, over the next week I took a bunch of "virgin" empty toner cartridges (I am not going to make any jokes here... in our industry a "virgin" empty was a toner cartridge that had already been used once, but never refilled...) and did experiments.

I went "old school" remanufacturing.

I pulled the cover and dumped out the waste toner only from the waste toner hopper.

I then removed the plug from the new toner hopper and added our toner to the cartridge.

Then I put it all back together.

Last, I took the cartridge and inserted it into the printer in question (we always had a test machines for every printer "engine") so I could verify how well the cartridge was printing.

Of course, the first few test pages looked fine.

The real test is a full cycle test running the cartridge until it runs out of toner (or until the output looks unacceptable.)

So, I queued up test prints to print continuously.

I would periodically take a look at the print quality (I would keep the first test prints as the "control").

Notes were made regarding the number of pages that had been printed during each periodic inspection.

Again, the cartridges would be run until they were completely out of toner.

This "run until empty, dump the waste toner, refill the hopper, run test prints" process was done on each cartridge until the print quality finally was deteriorating because the imaging drum was finally exceeding its useful life.

Sure enough, just as Francisco had told me, the cartridges could be refilled 2 - 4 times before they finally died.

I was EXCITED (to say the least)!

"Reducing" is good, "recycling" is good, but, "reusing" is KING!

Basically from day one, my thinking about our company's environmental impact was "reducing" is good, "recycling" is good, but, "reusing" is KING!

It's such a simple concept but it is HUGE.

Why most people don't see this is beyond me!

Printing fewer pages (reducing the use of toner and paper) is good.

Keeping your trash out of the landfill (recycling your paper and toner cartridges) is good.

Reusing is king because ever single time a toner cartridge is refilled the resources needed to create a new one were preserved.

There was no creating of the packaging for it (saving trees for the cardboard box).

Unlike recycling (where the cartridge and the box have to be shipped somewhere for processing and the shipping requires an energy expenditure) the cartridge stays in place and a tiny fraction of the original natural resources used to create a complete cartridge are used to refill the cartridge with toner.

TonerRefillKits.com is born

I realized that with all of our photography and video equipment that we used to create our toner cartridge remanufacturing training, along with the tools we used to create our instructions and intimate knowledge of the best suppliers, we could create the best toner refill kits on the market in the same way we had done with our remanufactured toner cartridges and our toner cartridge remanufacturing training.

When I look back at our first sets of instructions (from almost 20 years ago) I shake my head knowing how much better they would rapidly become.

But, the reality is, even back then they were head and shoulders better than any other instructions out there.

I thought as time went on other "RIY" (refill it yourself) toner refill kit manufacturers would look at what we produce and say, "Damn, we have to up our game!"

In fact, it's almost the opposite.

If you look at the instructions included with other refill kits, it is unbelievable how bad they are (and how those company owners can go home at night and say, "Yep! We done good!" is beyond me...)

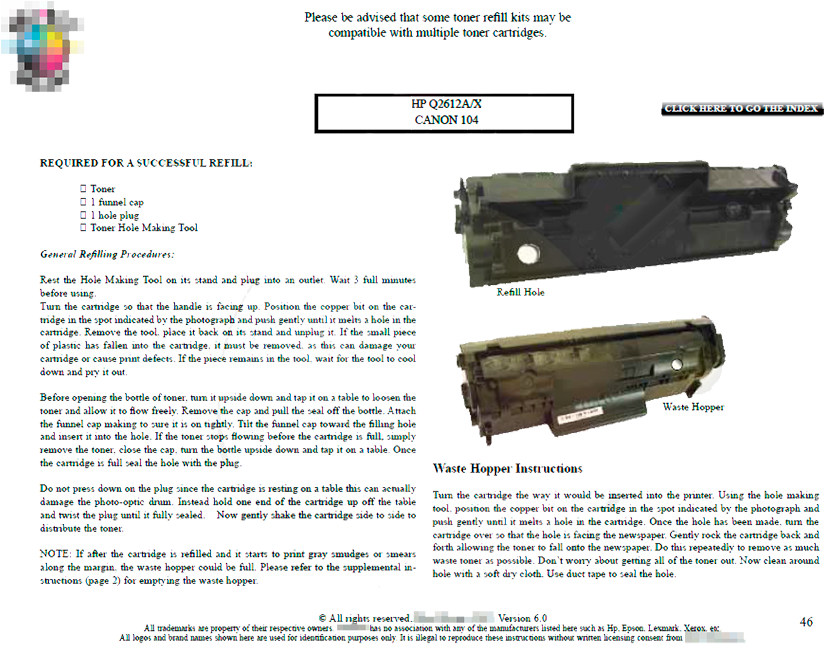

Here is a set of instructions from one of the companies you will find out there (one page, total):

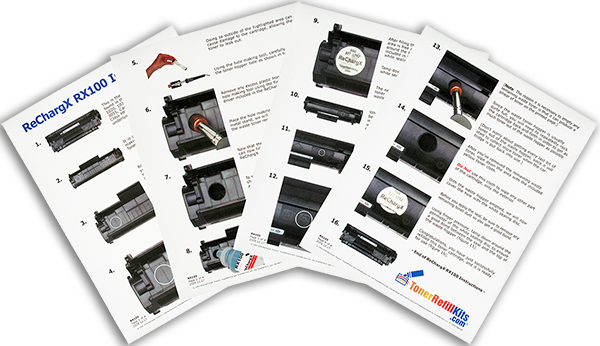

Here are the instructions we include for the same cartridge series:

You call that a "toolkit"? HERE's a toolkit!

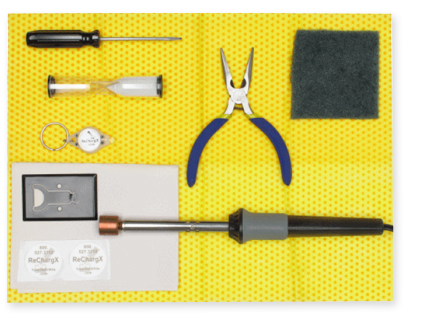

When we made our $12.95 ReChargX toolkit, we knew it had to include everything someone needed to perform the perfect toner cartridge refill.

When I say everything, I mean "EVERYTHING"!

I walked through our refill procedure step, by step, by step and every time I said something like, "On the rare occasion that the small, circular piece of plastic cut out by our "toner port tool" (aka, a soldering iron with a custom bit on it) falls into the toner hopper, use a pair of needle-nose pliers to remove it from the hopper", I would say, "What's the likelihood someone just happens to have a pair of needle-nose pliers laying around?" and then I would source a supply of inexpensive needle-nose pliers to include in the kit.

The same thing with the 3-minute sand timer (since people seem to have a real problem figuring out how long is 3 minutes they are supposed to allow the tool to heat up), the flat blade screwdriver, the little LED flashlight (to peer into the hopper in the highly unlikely even the small, circular piece of plastic falls into the hopper).

And, I even realized that when I said, "Grab a sheet of newspaper and put it on top of your work surface to make clean up after the refilling operation as fast as possible!" that many people these days (most people) no longer subscribe to the newspaper so we even include a "custom" "desktop protector" (a sheet of newspaper with our ReChargX-brand logo printed on it).

Since ecommerce on the internet was just getting started it came to me and "TonerRefillKits.com" was born.

100 varieties of toner refill kits created within a few short months

Since we already had pictures and instructions for dozens of toner cartridge types already in house for our training products, we were able to add 100 varieties of ReChargX-brand (our brand name) toner refill kits in a matter of months.

I set out to make the absolute best toner refill kits and then that meant we had to create the best website on which to sell our toner refill kits.

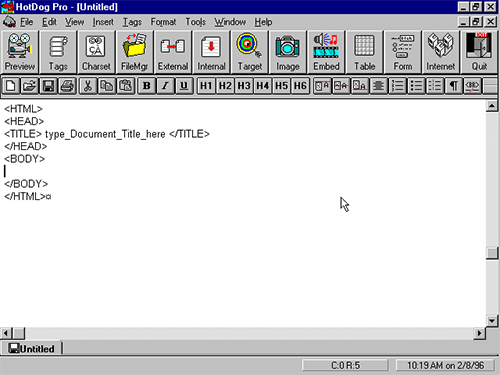

WTH is "HotDog HTML"?

Starting in July of 1999 and with our typical "if something needs to be done we'll figure out how to do it attitude" I created our TonerRefillKits.com web site, from scratch using a piece of software called "HotDog HTML".

Every single page was a one-off "hard-coded" page (ultimately growing to 11,000+ individually coded, standalone pages)

Our TonerRefillKits.com web site was connected to one of the first ecommerce platforms, a hosted shopping cart called, "Americart".

We turned on the website and shopping for its first purchases in December of 1999 and crossed our fingers.

Within a matter of a few weeks we were taking in orders daily and shipping our toner refill kits out of our offices.

In the very first year the number and dollar volume of orders we were taking in from the sale of ReChargX toner refill kits exceeded the revenue and profit we were making after 13 years in the full-blown toner cartridge remanufacturing business and our training business.

"Honey, that's not what I meant by "banner advertising", you're kidding, right..."

Again really early on in our online business Annette asked if I knew anything about "banner advertising". I said I knew next-to-nothing about it but would look into it.

A few days later I started running banner advertising on a site or two (you know, that really annoying add that used to appear (and far too often still does appear) on the top of a web site where some dope like me is paying far too much money in the hopes a visitor (like you) would have even the most remote interest in their product or service and that you will click on the ad).

But, be the funny guy I am (well, in my own mind, not only do I look like Tom Selleck (without the height, the hair, the moustache, the good looks (and without those way too short shorts who used to wear on Magnum PI)) but I also like to think I am a natural comedian. Annette begs to differ) I told Annette I had set up our banner advertising and she should be able to see on line before long.

I then said, "Okay, I'll show you a preview of our banner advertising on the company's site I bought it from."

Hoping I was kidding, she looked at me and said, "Honey, that's not what I meant by banner advertising, at all, you're kidding, right?"

Of course I was kidding.

But, I am not kidding, at all, when I say that banner advertising for us (or at least in the way "we" (I) did it), it didn't even come close to paying for itself.

Maybe I should try my much more fun idea of banner advertising...

"Holy cow, "buyer intent" PPC advertising will be HUGE!"

In the early 2000's I learned of a new method of advertising that was just coming on the scene called "pay per click" advertising from a company called Goto.com and I jumped on that, immediately.

The theory was incredible simple, you could pay to advertise based on "buyer intent".

If someone is searching for "HP Laserjet 1010 toner" they have "buyer's intent" and you can bid your way to the top of that search engine results.

The more you were willing to pay, the higher up you appeared in the search engine results.

My attitude was, "Holy cow, "buyer intent" PPC advertising will be HUGE!"

The results were excellent and the ROI was great, as well.

Goto.com became Overture.com, but the "big dog" was about to pounce.

Google PPC advertising is born and AdWords explodes our business

Though Google had offered advertising pretty early on (in the late 90's) they didn't offer what finally became accepted as Adwords until 2002.

We jumped on that as hard as we could and from the start bought the number 1 positions on 1500+ keywords (then 2000, 3000, 4000...)

Back in those days it was a pure auction (no "quality score", "page rank", etc.) and we bid aggressively and spent big.

We didn't just spend big, we spent insane (but really profitable) amounts of money on PPC earning a position for several years running in Google's top 250 advertisers club (not bad for a little company that started in our basement and went online only a few years before Google started offering AdWords.)

(When I say "insane", I mean INSANE! There's nothing that will make you sweat bullets like opening your AMEX bill and seeing high five-figure or low six-figure PER MONTH charges (all from Google!) will... (And, to avoid having that happen we would pay AMEX weekly so the bill we would receive at the end of each month would "only" be low five-figures. Years later I still shake my head in amazement how far we have come.)

Thanks to AdWords we exploded our business and our customer base and started doing business around the globe (157+ countries at last count).

"Behavioral Retargeting"? Oh, yeah!

Being the geek that I am (did I mention that? HA!) I love new, cutting-edge stuff.

In fact, also being serious, SERIOUS ADD/ADHD is my biggest liability.

(I am typing right now on my main desktop PC with three 24" monitors (and one 40" monitor on the wall across from me that autoplays motivational, educational, scientific, really interesting videos 'round-the-clock as my "background noise") and I have at least 30 tabs on each monitor (and windows buried behind the top window).)

But, I think it is also my biggest asset. I love constantly researching new stuff.

So, after learning and employing "buyer intent" marketing, I read about "behavioral retargeting".

Behavioral retargeting? Oh, yeah!

You've all experienced it but it basically is an advertisers dream.

Once someone has raised their hand and said, "Okay, I'm a little interested in what you have...", you can then display your ads to them when they go to other sites on the web.

Our favorite provider (because they were one of, if not the, first to offer retargeting) was "Fetchback".

As you see , their logo is a dog with a ball (you through a ball to your dog and what does it do? It brings it back...)

Perfect time for a seque about our love for dogs...

As I mentioned at the beginning (seems like weeks ago, right???), I started The Laser Group with our Sheltie "Winky" at my side in the basement of our townhome.

Ever since then dogs have always been at our sides.

And, we found the majority of our employees loved dogs, too.

As if all of that wasn't cool enough, our customers seemed to love dogs, too.

So, ever since we moved into our "new" headquarters (over 12 years ago) we have invited all of our employees to bring their dog pals with them to work.

It might seem weird (what, us do something "weird"?), but we love it!

Okay, here is the gratuitous picture of the best dog in the world, "Daphne" (currently our only dog, but, we're always on the hunt for more...)

(BTW, that picture was absolutely, positively pure luck. My best friend/mentor of 50 years (yes, I am "older than dirt") is a master photographer and he told me many, many (far too many!) decades ago, the best pictures you will ever take are the ones where you were lucky enough to have your "camera" with you. That's how little "Boston Blackie's" perfect picture came about.)

We needed a "drum dumper"!

When we first started making our ReChargX brand toner refill kits, we would buy toner made to our specifications in bottles and label the bottles in house with our ReChargX labels.

As our ReChargX toner refill kits sales volume increased dramatically, we could no longer justify having thousands and thousands of pre-filled bottles shipped to us (for two reasons, number 1 being toner in bottles is WAY more expensive than toner in bulk. Number 2 being the storage space requirements for toner in bottles is orders of magnitude higher than toner in bulk).

We needed (once again) to learn about bulk vs. bottles, step up our game and start buying our toner formulations in bulk.

The intermediate step our toner manufacturers suggested was buying toner in 10 kilogram bags.

We knew we were already beyond that point and started buying toner in 55 gallon drums (with 250 - 500 pounds of toner in each).

Since we had never dealt with moving 250 - 500 pounds of toner around before, we needed our first forklift.

Even more important (and daunting) than that was another piece of equipment we needed (and never heard of before)...

We needed a "drum dumper"!

When you need to move toner from giant vessels down into precise amounts in small bottles, the first and most important thing you need to do is raise the giant barrel of toner and invert in the process.

How do you do that? We needed a "drum dumper", of course!

Fortunately the ceiling height in our building was high enough that it accommodated the drum dumper and we were on our way.

Investor's Business Daily writes our story!

While we weren't completely surprised when Recharger Magazine and R&R News featured us as cover stories, we were stunned to get a call from a writer at Investor's Business Daily indicating he wanted to come out and do a story about TonerRefillKits.com. We were delighted to have him come out and even more delighted (as always) that thanks to what we refer to as "The best team of employees a husband and wife business owner ever had the pleasure of working with" we were deemed worthy of their attention.

Just as had happened within our industry publications

Always wanting to stay ahead we were one of the first companies in our industry to offer online live chat.

We were also one of the first (if not the first) in our industry to use "retargeting".

514 Reviews - 9.86 out of 10 on ResellerRatings.com

In addition we started using an online review service (ResellerRatings.com) in the first year they came on line allowing our customers to review our products, service, support, everything about our company.

And, seeing the possibility of competitors paying for favorable reviews we went the complete opposite direction and from the very start, we refused to pay for favorable reviews (never have, never will) and asked our customers, "Please leave an honest review about your experience with our company." Nothing more, nothing less.

That straightforward approach earned us our 9.86 out of 10 rating (we dropped ResellerRatings.com a few years back when they were bought out and the cost of their services exploded by nearly 20X what we originally paid when we started with them just a few years earlier).

4,984 Reviews - 4.9 out of 5 on ShopperApproved.com

After leaving ResellerRatings behind we went with ShopperApproved.com.

The venue for our reviews had been updated but, as always, we remained committed to our "We are the best in the world at what we do!" philosophy.

We still had the best products, the best customer service, best support (all provided by the best employees!) and best guarantee.

So, at SiteJabber (ShopperApproved) we earned 4.9 start and received 4,984 customer reviews.

(Again, no fake reviews, no paid-for reviews, we don't offer any incentives to our customers to say nice things about us... these are REAL reviews).

And, that approach keeps winning and winning and winning.

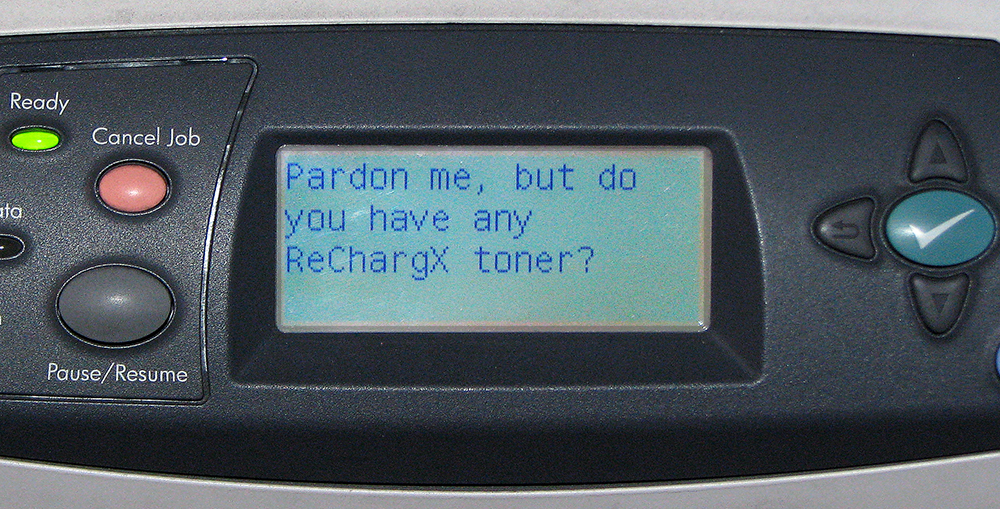

"Pardon me, but do you have any ReChargX toner?"

Our ReChargX-brand toner refill kits became so popular, not only were customers around the world seeking us out, but even printers were asking to be fed ReChargX toner?

(If you are a geek and you want to program your older HP printer's LED display to do the same thing, here you go: Make My Printer Say Naughty Things)

506,000+ people watch a video about toner?

When Youtube came on the scene (seems like it's been around, forever, but it hasn't...) I told Annette I wanted to make videos about toner.

She asked, "Who in their right mind would want to watch a video about a toner cartridge?"

I said, "Anyone who had that machine or cartridge and wanted to know how to save money on that supply."

One of the first videos I produced ("state-of-the-art" quality back then (well by comparison...)) was on that super-exciting topic...

"Hewlett Packard Laserjet P1005 Toner Refill Process" (I know, exciting, right?)

Little did I know 506,000+ people around the world would watch a video about toner!

WTH is the "A.T.E."???

At one point I decided I needed to sum up what toner cartridge refilling is all about in a "commercial".

I wasn't going to run the "commercial" on TV, I was going to run it on Youtube.

I told Annette about my idea and she said, "Wow, that is going to be so boring... a toner commercial!"

I said, "No, it's going to be just like the "hero's journey" and there is going to be a bad guy."

She asked, "Okay, who is the bad guy in our industry?"

I said, "Easy! The "A.T.E." is the bad guy."

She said, "Okay, WTH is the "A.T.E."?"

And I said, "I can't tell you, you'll have to watch the movie!"

That's our story (so far!) and we thank all of our customers from the bottom of our hearts because none of this would have been possible, without all of you!

But, with as fast as the internet technology was has changed, the bottom line is our philosophy and approach to business is the same as it was from day one more than three decades ago...

Offer the best products we possibly can, the best service and support we possibly can, all backed by the industry's best (and still only) "No time limit - no fine print" guarantee.

Little did we know on that fateful day in 1987 that changing my first toner cartridge in an HP Laserjet Series II would take us all the way to our retirement years.

It has been one heckuva journey and we'd gladly do it all over again (assuming we were in our early 30's "all over again"!)

As Annette and I have said in just about every single communication we have ever sent out to our customers, "Without all of you, there wouldn't be a TonerRefillKits.com"

We want to say that, again, "Thank you, from the bottom of our hearts because none of this would have been possible, without all of you (our customers)!"

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

"Wait, Duane, what's the #1 problem in the industry (and what about the Chinese, the U.S. Supreme Court, Davos and Carl Icahn)?"

Here's the inescapable fact...

All of us in the toner industry know the OEM cartridge sets the bar for "perfect" print output.

The goal of every aftermarket cartridge manufacturer, remanufacturer, refill kit manufacturer, toner manufacturer, etc. is (or should be) to make their output look as good as that of the OEM.

Countless competitors come nowhere near producing print output as good as the OEM.

Quite a few produce products that do produce darn good output (but still not as good as the OEM.)

Then there is a small number of us who do produce products that equal the print quality of the OEM.

And therein lies the NUMBER 1 problem in our industry (but, most people in our industry still don't see it - fortunately, we realized it from the very beginning).

If the OEM sets the bar and continues to do their job right, if we do our job right, and if our top competitors do their jobs right, we are all selling products that produce the exact same thing: text/images on paper that equal that of the OEM.

What is an item referred to that is exactly the same no matter which of thousands of suppliers?

A "commodity" item.

What is the "marketing" plan most companies come up with when they feel they are selling what they perceive to be a commodity item?

"We must sell ours cheaper!"

That leads to a "race to the bottom".

Only a small minority of competitors realize that the "race to the bottom" guarantees no one wins and they then seek to differentiate their business in other ways (as we did, best service, live help, live answering of phone and the strongest guarantee in the world).

Another huge disadvantage everyone in our industry faces is that a competitor with even a modest ad budget can advertise side-by-side with the OEMs (it's not like the "old days" where only HP, Brother, etc. could afford to advertise in the magazines, on TV, on the radio, in newspapers, etc.)

And, unlike the "old days" where advertisers had to pay to advertise to "everyone" (in a magazine, for example, where a tiny fraction of the readers might want or need toner for their particular brand) technology now enables all competitors to advertise directly to someone who has "behavioral intent" by virtue of the keywords they use in the search engines (and thereafter, once the user/searcher had telegraphed their interest to the advertiser, they can be "re-targeted" for pennies.

That "Number 1 Problem" is also the number one opportunity for someone to seize on which can be done with the huge advantages available in the "influencer"-driven world economy.

"Green"/recycling influencers abound on the internet, "DIY" experts abound on the internet, "Beat the man" experts abound on the internet.

Introducing typical aftermarket toner cartridges to the followers of those influencers through their online presence would have some benefits, but introducing a company that was built from the ground up on the concept of reusing, "beating the man" (the OEMs) at their own game by refilling something they claim "can't" be refilled, having the "DIY" pleasure of bringing something back to life that was designed to be thrown away, and then saving 70% on average in the process, is worthy of their attention and influence.

The U.S. Supreme Court, finally, FINALLY!, issued an "en banc" decision on what someone can do with their empty toner cartridge. Though our dear friend and mentor, Art Diamond, predicted it would happen, he didn't live to see his prediction come to fruition.

But, in typical "Art Diamond said it so you can take it to the bank!" fashion, the Supreme Court said, "You Buy It You Own It!".

Why was that a big deal? Because once and for all the question of what can be done with an empty toner cartdridge was settled, once and for all.

You bought that cartridge and when it is empty if you want to refill it, that is perfectly legal for you to do. You bought it, you own it!

Something else industry game-changing that has come to the fore is China shutting down the importation of e-waste from western and European countries. Their willingness to be the world's landfill ended a little over a year ago.

In fact, that problem is coming to a head, now, with many cities and counties in the USA abandoning their recycling efforts because what used to be a money-making (or at worst, a break-even endeavor) has become a huge money-loser overnight. Around the world the situation is just as pressing.

(Update January 25th, 2019: The world leaders, movers and shakers at Davos just emphasized the need for countries around the world to step up the "Circular Economy" in an effort to "tip the balance" against climate change.

What is the ultimate in the "Circular Economy"? Reusing what has already been made.

For nearly 20 years ReChargX toner refill kits have been doing exactly that. We didn't even need to fly our corporate jet to Davos to figure that out! (okay, we don't have one, but, if we did...)

(For those who love reading reports written by experts, here is The Circularity GAP Report 2019

As for Mr. Icahn, at the very beginning of this "novelette" I mentioned ours is an industry with amazing similarities with an industry that Carl Icahn is betting his personal billions on.

Though it has escaped most people's attention (until you point it out and then they say, "Wow, you are right, I hadn't thought about it, but it's true!") auto parts stores are popping up EVERYWHERE!

While "reduce-reuse-recycle" has been talked about for decades, we still live in what is widely seen as a "throw away" society.

But, billionaire investors (like Mr. Icahn) see that without any fanfare, more and more people (more than ever before) are prolonging the lives of their vehicles by having them repaired or repairing them on their own rather than simply consigning them to the junkyard.

Many of the acquisitions he has made are companies that cater to the "DIY" market (AutoZone, Pep Boys, Auto Plus, O'Reilly, etc.)

Contrary to popular misconceptions, most "shade tree mechanics" aren't motivated by just the savings, they are motivated by being able to do it themselves, take great pride in taking something "broken" and fixing it, working with their hands, by "beating the man".

That's our toner refill kit customer in a nutshell (and it's no surprise, that's me in a nutshell).

Of course saving money is great and they love that (and our profit margins are excellent on those kits, as well - that "Win-Win" approach I mentioned early on) but rather than junking the cartridge, throwing more stuff in the landfill, paying "the man", etc. they know they (or one of their employees) can refill their toner cartridge in minutes.

And, what those "DIY" auto parts stores realized a long time ago is many people who want to do DIY aren't likely to finish the job or like it enough that they are going to do more of their own service work in the future.

Rather than lose their business they offer either service bays to their customers where tools and help are available or they offer complete repair work if the prospect no longer wants to get their hands dirty.

We do the same thing with our compatible cartridges.

Many people will do their own refilling (or at least be drawn to us by virtue of looking to do their own refilling) and then decide the no longer want to do it or they simply need the fastest way to get their printer up and running and then want a "ready to print" cartridge.

That's why we offer our ReChargX compatible cartridges along with our refill kits.

It's the perfect marriage!